"Save money! Save money! Rope access saves money! Why aren’t you using rope access? Don’t you want to save money??"

If you follow rope access companies like us, you’re probably tired of hearing this message from all of our business development and marketing folks. And if you’ve declined using rope access despite our incessant cost savings message, then that probably means there are other factors you hold in priority over saving some bucks. Unfortunately, we haven’t done a very good job at highlighting some other benefits of rope access. Sure, saving money is a major benefit, but that’s not always a guarantee when using rope access. Today, I’m going to take a step back and discuss a different advantage to using rope access. And this is the ability for teams to be flexible on a dynamic work site. When there are many moving parts, people, machines, and/or environmental factors you can’t control, using rope access can help you stay flexible to these dynamic changes while keeping momentum of the project going. Below are three examples of how our rope access teams catered to a dynamic work environment.

1) Unpredictable Weather

In this scenario, our rope access teams were involved with completing some concrete repairs on a dam. The dynamic factor here was the potential torrential rains that could occur. Any major rainfall would result in high water volume going through the dam. If scaffolding or swing stages were present, it would have been a major ordeal to dismantle this equipment before a rain event. Considering there was no control over this environmental hazard, the use of scaffolding or swing stages would require a great deal of extra resources to mitigate the risk. And, potentially create a very unsafe work place.

In this case, using rope access made sense. If an unpredicted rain event were to occur, there was no bulky equipment that needed extensive time dismantling. All the equipment used for rope access is already demobilized after every shift. There would be little risk of equipment damage. In the end, using rope access for these concrete repairs meant the whole project didn’t have to seize due to any heavy rains.

2) Conflicting Work Groups

For this second scenario, Pacific Ropes was commissioned to paint the ceiling of an area in a mall. However, the area that we needed to paint was directly above many kiosks. These kiosks still remained in operation and could not temporarily close down for the ceiling paint job, which would have happened if scaffolding had to be built to access the ceiling. Because these kiosks were operational during the day, all work had to be completed in the evening when the mall was closed. This meant any access equipment would need to be mobilized and de-mobilized daily. Scaffolding or any other temporary platform was not appropriate for hese dynamic requirements.

Utilizing rope access in this scenario meant all the vendors below could continue their business during the day as per normal without being affected by the work done above. Our rope access teams were able to mobilize and demobilize each night without interfering with any mall business.

3) Conflicting Schedules

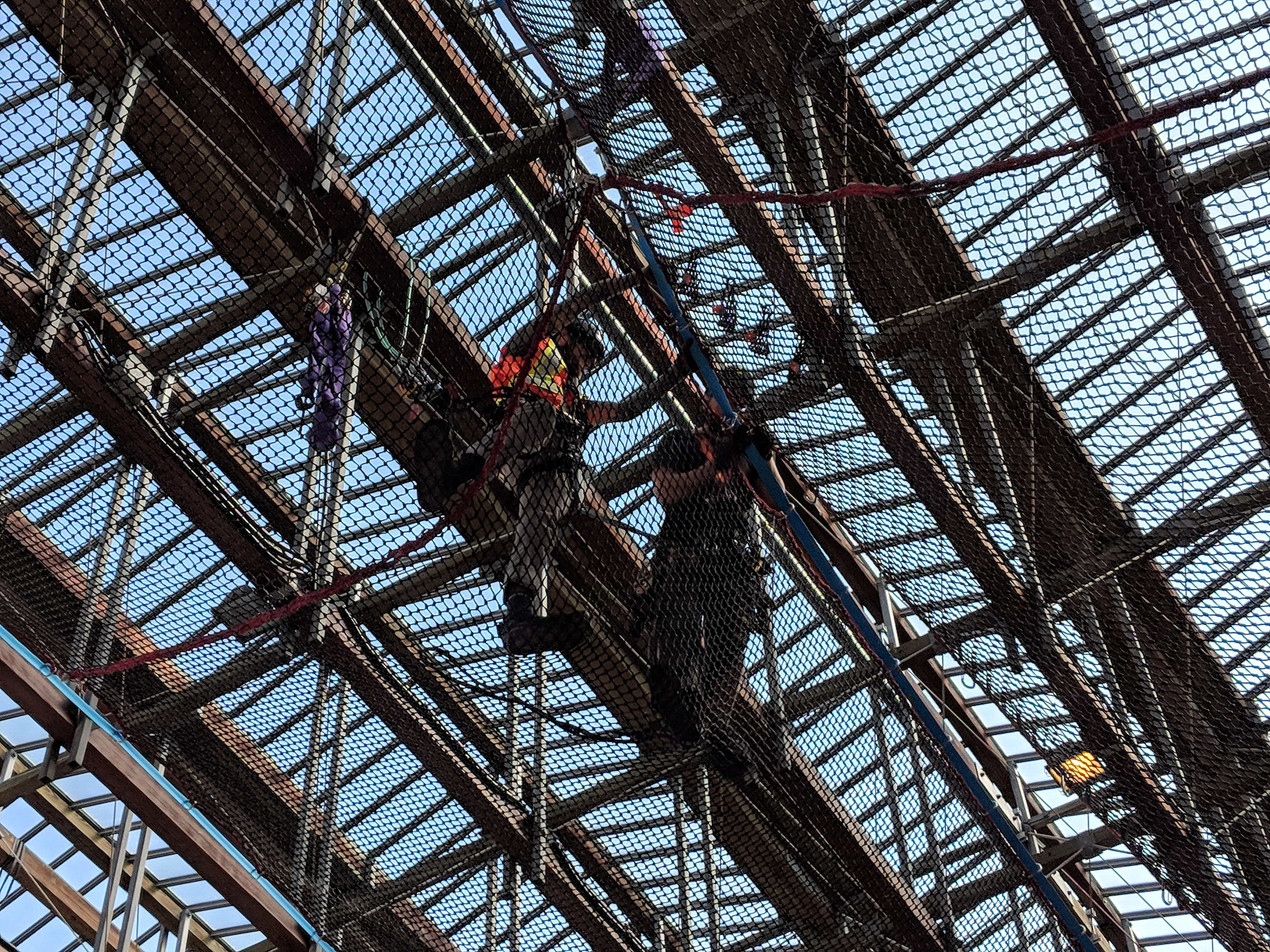

For this last scenario, Pacific Ropes was tasked to complete some dry-ice blasting and re-coating of some ceiling beams in a university. However, the area that needed this work was directly above the area the university used for their convocations. Because the work was scheduled during the same time as these convocations, the university could not cordon off any areas for scaffolding.

Instead, they decided to go with the rope access option. Using rope access, we set up a tensioned netting platform below the beams to hold any construction debris and to allow our workers to access the full length of the beams without interfering with any university events below. Although work was suspended when the events were happening, none of our work site had to be demobilized in order for these events to happen as planned. When we came back to site, our teams were able to continue their work without wasting time mobilizing again.

These three examples demonstrate the flexibility of using rope access when projects are faced with conflicting requirements. Rope access personnel can provide labour, access, and rescue. Hiring a rope access team and utilizing their trifecta services allows Project Managers to meet the varying demands of the different factors involved in any complicated project without compromising on the delivery of that project. It allows for efficiency and momentum without sacrificing quality or safety.

To get an idea of whether rope access is a suitable method to use on your projects, schedule a call with us!